Materials, Free Full-Text

5 (101) · $ 30.99 · In stock

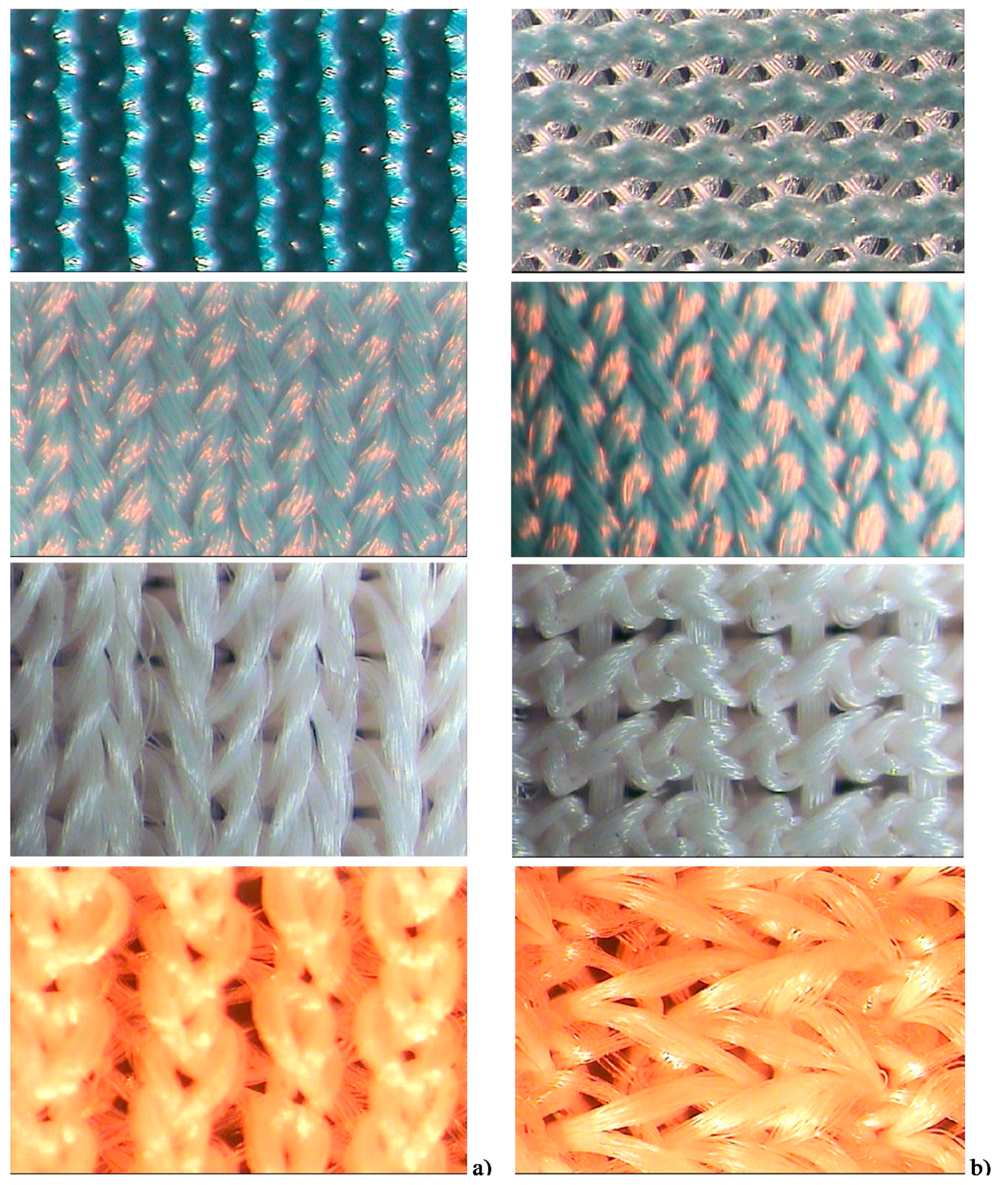

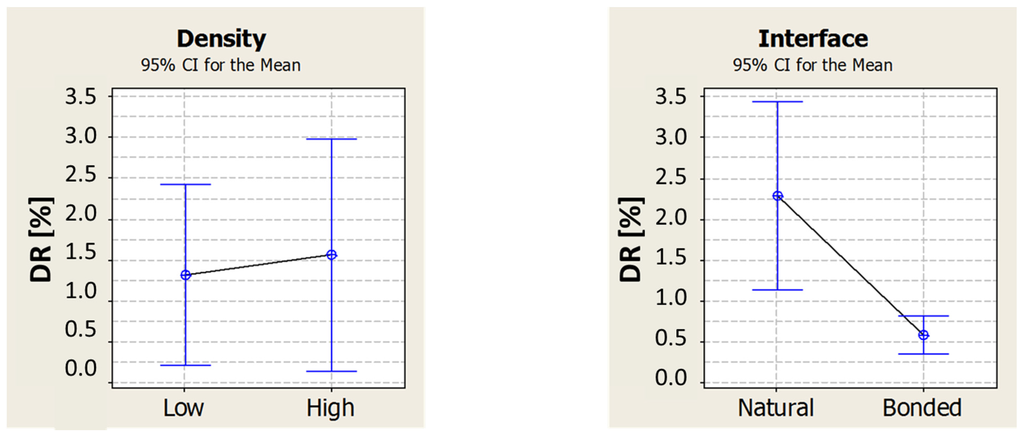

The aim of this study is to develop a mathematical model for the prediction of compression pressure based on fabric parameters, such as engineering stress, engineering strain and engineering modulus of elasticity. Four knitted compression fabrics with different fibrous compositions and knit structures were used. Rectangular-cut strips were employed for the force–elongation characterization of the fabrics. The experimental pressure values between the fabric and rigid cylinder were assessed using a Picopress pressure measuring device. The mechanical and physical parameters of the fabric that influence the interface pressure, such as strain, elasticity modulus/stress and thickness, were determined and integrated into Laplace’s law. A good correlation was observed between the experimental and calculated pressure values for all combinations of fabrics, mounted with variable tension on the cylinder. Over the considered range of pressures, the difference between the two datasets was generally less than 0.5 mmHg. The effect of washing after five, ten and fifteen washing cycles on the fabric–cylinder interface pressure was found to be significant.

Organic Cinema 4D Materials - Free Cinema 4D Texture

Materials, Free Full-Text

Materials, Free Full-Text

Hazardous Material Vector Art, Icons, and Graphics for Free Download

Materials, Free Full-Text, Heat Transfer

Materials, Free Full-Text

Materials, Free Full-Text, Graphite

Tribology of carbon nanotubes - About Tribology

Embroiderymaterial Beginner Embroidery DIY Kits Hanging Garden

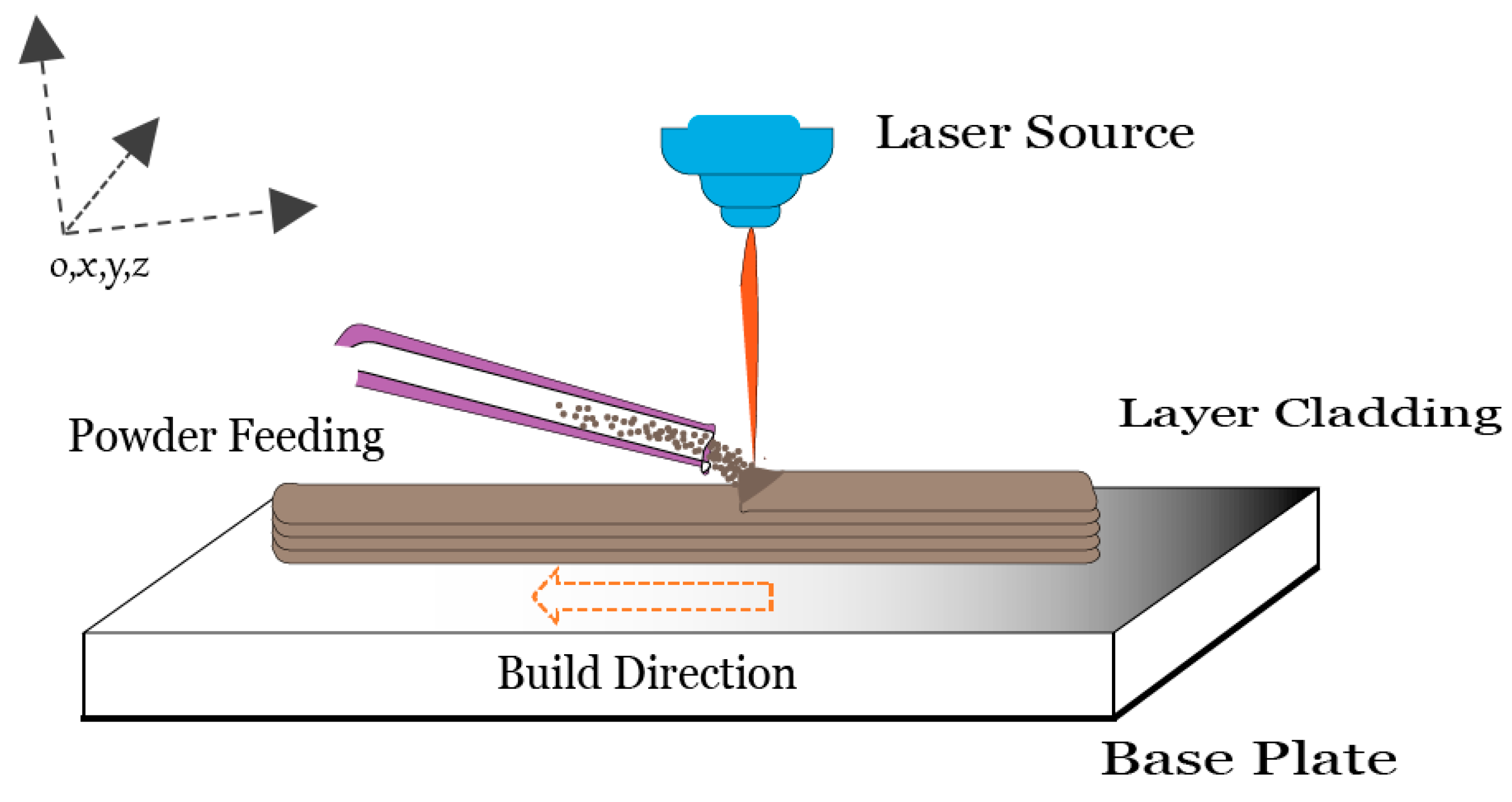

Materials, Free Full-Text, values mm2 laser

Engineering Thermoplastics Guide. Chapter 4: Advancements in

2690fb44496420cb9dcb19a8775bcc2d4907e2d5.180px.jpg

ECAS Spring Course Planning: Tips from the Library – Emory

Metals, Free Full-Text, simulation unclogger