PART 8 BITUMINOUS MATERIALS - ppt video online download

5 (785) · $ 23.99 · In stock

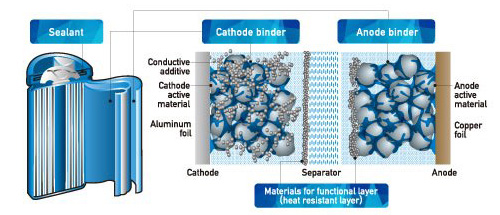

Definitions: Binder: A material used to hold solid particles together, i.e. bitumen or tar. Bitumen: A heavy fraction from oil distillation (also occurs as part of natural asphalt). Tar: A viscous liquid obtained from distillation of coal or wood. Rarely used in construction currently in the UK. Asphalt: A mixture of bitumen and mineral filler. Note that Hot Rolled Asphalt is a road surfacing material. Mastic: An adhering asphalt which is placed with trowelling. Macadam: A road construction material with binder and coarse aggregate. Tarmacadam was the first road surfacing material.

PART 8 BITUMINOUS MATERIALS

8.1 Introduction. Definitions. Safety. Production. 8.2 Binders. 8.3 Bituminous mixtures. 8.4 Applications.

Bitumen: A heavy fraction from oil distillation (also occurs as part of natural asphalt). Tar: A viscous liquid obtained from distillation of coal or wood. Rarely used in construction currently in the UK. Asphalt: A mixture of bitumen and mineral filler. Note that Hot Rolled Asphalt is a road surfacing material. Mastic: An adhering asphalt which is placed with trowelling. Macadam: A road construction material with binder and coarse aggregate. Tarmacadam was the first road surfacing material.

The fire point is the temperature at which the binder will burn. Water will spread a bitumen fire. The materials are generally used at temperatures high enough to cause severe burns. Both the materials and the vapours are potentially carcinogenic.

Kerosene (parafin) Lubricating oil. Base Bitumen. Diesel oil. Petroleum. Light oil. Blending. Penetration Grade Bitumen. Fluxing. Emulsification in water. Oxidation. Cut-back bitumen. Bitumen Emulsion. Blown Bitumen.

8.1 Introduction. 8.2 Binders. Properties. Testing. Binder Mixtures. 8.3 Bituminous mixtures. 8.4 Applications.

Viscosity All bituminous materials are viscous, i.e. when subject to a long term load they deform continuously. Softening point This is the temperature at which the binder softens to a pre-determined point.

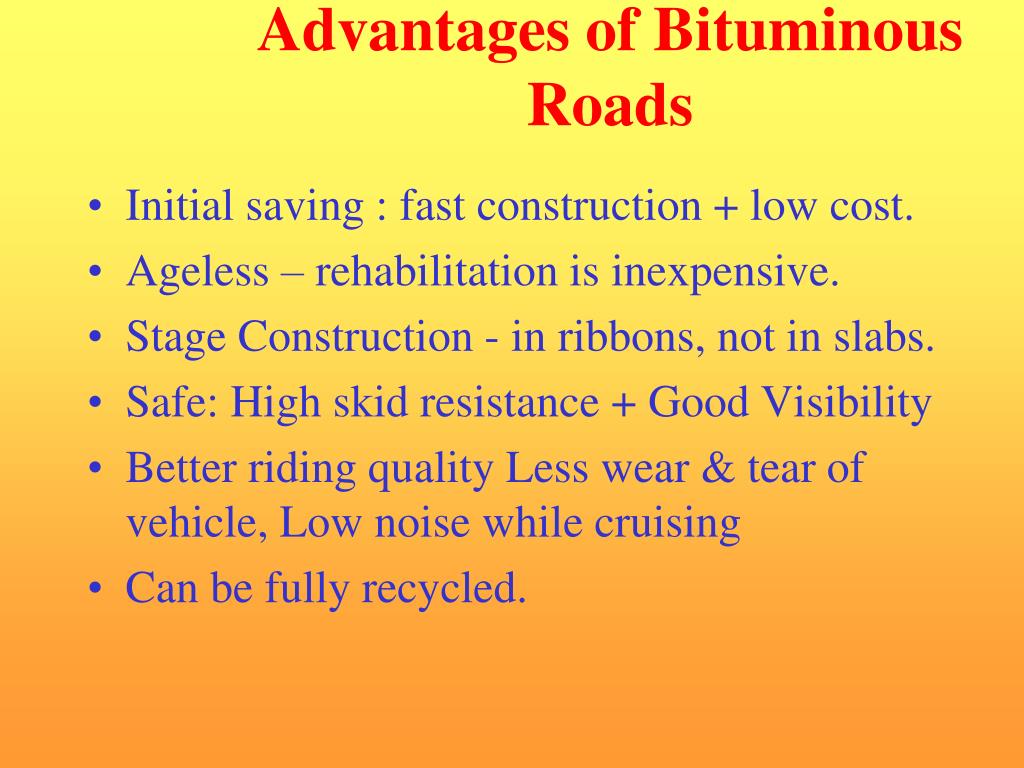

Intrinsically durable, they oxidise, polymerise and lose light oil components when exposed to air and heat but all of these processes just make then harder. Virtually impermeable if well compacted. Intrinsically resistant to plant growth. Softened by high temperature and solvents (often by fuel spills)

Sliding plate viscometer In this apparatus a thin film of binder is sheared between two glass plates and the shearing force is measured. Standard tar viscometer In this test the time taken for a set volume of tar to flow through an opening at a given temperature is measured. Penetration test For straight bitumens viscosity is normally measured with a penetration test. A 1mm diameter needle is loaded with a weight of 100g and the distance it drops into a bitumen sample in 5 seconds is measured (at 25oC). A bitumen is referred to as 70 pen if the penetration is 7mm. Softening point test To measure the softening point a small sample is melted, cast in brass ring and cooled and then progressively re-heated until it deforms (i.e. flows ) by a given amount.

Cutbacks This term is used to describe a mixture of a binder and a light volatile oil. They are liquid at low temperatures until the volatile oil evaporates.. Due to the release of solvents into the atmosphere they are now rarely used. Emulsions When mixed with water binders will generally settle out. An emulsifier must be added to give a stable solution. Bitumen paints are made this way. The water evaporates and the bitumen remains on the surface. The current types of cold rolled materials are based on emulsions.

The sensitivity to temperature changes is decreased. The beneficial properties are lost with prolonged heating. The increased elasticity and penetration resistance makes this material ideal for expansion joints and repairs in roads.

8.1 Introduction. 8.2 Binders. 8.3 Bituminous mixtures. Components. Properties. Testing. 8.4 Applications.

Coarse aggregate (retained on 2.36mm sieve) Fine aggregate (passing 2.36mm sieve but retained on 75) Filler (passing 75), may be cement. Binder: Bitumen etc.

The cost is reduced. The strength is generally increased. If the mix has to be laid hot the aggregate must also be heated (at considerable cost) May fail due to loss of adhesion between aggregate and binder.

Penetration test This test is similar in principle to the penetration test for binders but on a larger scale. The steel pin is 6.35mm (0.25 ) diameter and the load is 10 N/mm2. Marshall test In this test asphalt mixes are made at several different binder contents. Cylindrical specimens are loaded in compression on their curved surfaces. The maximum load (stability) and the deformation (flow) is recorded. Dissolution of binder There are a number of BS tests which involve dissolution of the binder in solvents. The mix proportions and the nature of the binder may be determined. Percentage refusal density This test is used to measure compaction in road construction. The density of a core from the road is compared with the maximum density achievable using heat and heavy compaction (the refusal density).

8.1 Introduction. 8.2 Binders. 8.3 Bituminous mixtures. 8.4 Applications.

Applications Roads Tanking Roofing

Wearing course. Base course. Roadbase. Sub-base. Subgrade (limestone) Lower base (crack resistant)

Asphaltic concrete: Asphalt in which the aggregate particles are continuously graded to form an interlocking structure. Surface dressing: Sprayed bitumen binder with stone chippings rolled on. This is used for repair work. Slurry surfacings and micro asphalts: Bitumen emulsions with selected aggregate combinations. Also used for repair. Stone mastic asphalt: gap graded asphalt composed of a coarse crushed aggregate skeleton with mastic mortar.

Hot Rolled Asphalt Surface

Rutting (shear failure) Potholes (bond failure) loss of skid resistance (viscous flow) Lower courses. Cracking (Fatigue failure) Breakdown due to failure of lower courses (e.g. reflected cracking from dry-lean concrete)

Asphalt trowelled onto walls after casting. Base slab cast on layer of mastic asphalt.

8 Sustainable Applications of Nanoclays - Nanografi Nano Technology

PPT - Bitumen Presentation PowerPoint Presentation, free download - ID:5210251

Bituminous Materials

Bituminous Materials. - ppt download

Best Games on Apple Arcade This Week - CNET

8. bitumens

8. bitumens

SOLUTION: Bituminous materials - Studypool

The 3 Best Android Tablets 2024

PPT - Bitumen Presentation PowerPoint Presentation, free download - ID:5210251

The 3 Best Android Tablets 2024

PART 8 BITUMINOUS MATERIALS - ppt video online download

How to Gamify Microlearning with PowerPoint Templates

PART 8 BITUMINOUS MATERIALS - ppt video online download